Optical pumping is the method used to excite the atoms from the ground state into a higher state in order to bring about the necessary population inversion needed for lasing to occur in solid state lasers. This population inversion is brought about in different ways for the 3-level (Ruby) and 4-level (Nd:YAG) laser systems. However both require atoms to be excited from the ground state into a higher energy state and this is done using optical pumps.

The three main types of optical pumping lamp used for solid-state laser are

(i) the quartz-halogen lamp (used for both Nd:YAG and Ruby)

(ii) the halogen arc lamp (used only for Nd:YAG)

(iii) the incandescent lamp (used only for Nd:YAG)

Depending on the type of laser output required there are different methods of pumping the laser cavity. If the output required is to be pulsed then the optical pump must also be pulsed (Note: there are methods of changing Contimuous Wave (CW) laser outputs into pulsed form but these methods are not covered here. The methods described here are simply to do with the output from the gain medium without any laser accessories such as Q-switching and cavity dumping). For a pulsed laser output the laser medium is “flashed” with light rather than being continuously pumped. The optical pump mentioned above in (i) is used when a pulsed output is required and the optical pumps (ii) and (iii) are used when the laser output required is CW as these provide continuous pumping to the laser medium.

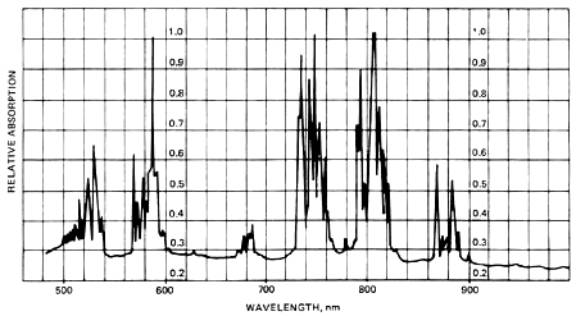

Below the absorption diagram for Nd:YAG can be seen. From this it can be seen that the two most important pumping regions for this type of laser are the 730-760nm and the 790-820nm regions since these are the wavelength values for which the Nd:YAG absorbs most photons. Since both of these regions are near the infrared region, absorption of photons of these energies wont cause much heating of the lasing medium and so there is no degradation in the amplification qualities of the medium due to overheating. There is another range of wavelengths for which the Nd:YAG shows good absorption but this range is near the ultra-violet and so would cause heating of the amplification medium. This absorption range is therefore not used for pumping the amplification medium.

Fig 1. Absorption spectrum of

Nd:YAG

Since most of the atoms are in the ground state in the Nd:YAG to begin with (and remembering that in a four level system the ground state is not the lower lasing level), it requires relatively few atoms to be excited into the upper lasing level for the population inversion required for lasing to occur. Relatively weak pumping of the medium is therefore required for lasing (assuming that the lower lasing level depopulates into the ground state rapidly, hence retaining the population inversion between upper and lower lasing levels).

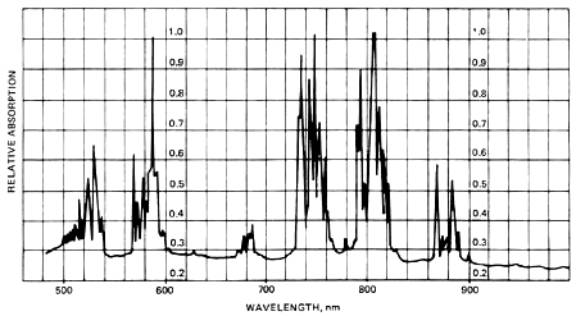

Fig

2. Absorption spectrum of Ruby

As we can see from the above absorption spectrum of the Ruby rod there are two broad absorption spectrums centered round 400nm and 550nm. Therefore light in the blue-green part of the spectrum is very effective for pumping the Ruby rod.

In a Ruby laser the ground state is the lower lasing level. It therefore takes an intense amount of pumping to create the required population inversion for lasing to occur. This is because most of the atoms reside in the ground state prior to pumping and these must be pumped into a higher energy level before a population inversion occurs. If these lasers were to be operated in CW it would take a large amount of pumping to maintain the population inversion. This large amount of energy causes great heating and so extremely efficient cooling systems are required for CW Ruby lasers if the rod is not to overheat and destroy the lasing action. Because of this the Ruby laser is usually operated in pulsed mode only. Although CW Ruby lasers have been built we will not discuss the pumping of such lasers here since they are not normally used.

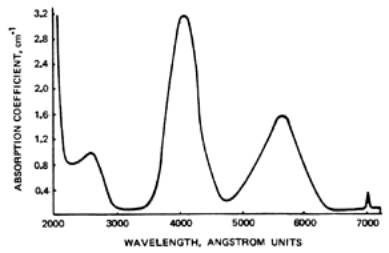

Below can be seen two common designs of flashtubes used in the optical pumping systems that are commonly used to pump the amplification medium in the solid state lasers. The first is a liner design that is “flashed” by passing a current through a noble or halogen gas. Krypton is the most effective for the Nd:YAG laser since it emits light of wavelength that corresponds with the absorption bands of the Nd:YAG but due to cost factors xenon is usually used even though it is less effective. Xenon has good emission in the blue-green spectrum of light and so is commonly used to illuminate Ruby rods for laser action to take place. The linear design is usually encased in one of the reflector setups described later. The arc length and the diameter of the flashlamp are usually chosen to be the same as that of the laser rod.

The second design for these types of flashlamps shown below is the helix design similar to that used by T.Maiman while demonstrating the first Ruby laser in 1960. The flash tube is coiled in a helix and the lasing rod is placed within this helix. For best pumping the helix is coiled tightly round the rod and immediately surrounded by a diffuse cylindrical reflector.

These two types of flashlamps are used as pulsed optical pumps with pulsed Nd:YAG lasers and with Ruby lasers. Due to the pulsed nature of the optical pumping the laser output will also be pulsed.

Fig 3. Two designs for flashlamp

optical pumps

The arc lamp shown below is used to illuminate the Nd:YAG lasing rod when continuous pumping is required (since the Ruby laser cannot be operated in CW mode, arc lamps aren’t used with Ruby lasers). The lamp contains a high-pressure (2-4 atmospheres) noble gas in an inner capsule with metal electrodes at each end. This is then encased in a water envelope to cool the lamp since it is in continuous operation. The gas is ionized by a high-voltage pulse and then is maintained by a constant voltage across the electrodes. Although krypton lamps are more expensive than xenon lamps, in this case krypton arc lamps are used since they give a far superior continuous output than the xenon lamps.

Fig

4. Arc lamp Continuous Wave Optical Pump

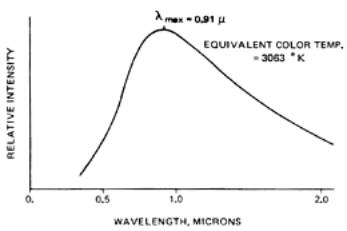

The most commonly used incandescent lamp is the tungsten filament lamp since the relatively inexpensive. These lamps provide a cheap alternative to the krypton arc lamps for pumping CW Nd:YAG lasers. Again since these lamps are used for pumping CW lasers and since the Ruby laser isn’t operated in CW these lamps aren’t used as optical pumps for Ruby lasers. These lamps have a continuous emission that is characterized as a hot blackbody emission spectrum shown below. Because of this continuous emission it is easy to see that part of the emission coincides with the absorption spectrum of the Nd:YAG laser and so can be used as an optical pump. However a lot of the light emitted by the lamp is wasted since it is not absorbed by the lasing medium. Regardless of this fact the low cost of these lamps makes it feasible to make a powerful enough lamp to provide enough illumination at the desired wavelength to make it an option as an optical pump.

Fig

5. Emission spectrum of the Tungsten Filament lamp

Linear Flashtube Pumping Geometries

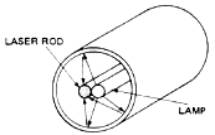

One of the more common geometries used with linear flashtubes is the elliptical setup as shown below. By placing the rod at one of the focii of the ellipse and the flashtube at the other focii of the elipse the majority of the light from the lamp is reflected onto the laser rod so the maximum amount of light from the lamp reaches the lasing rod.

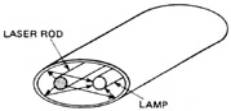

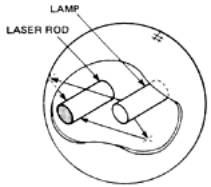

Another common geometry used is the cylindrical layout shown below with the lamp and laser rod placed side by side in the centre of the reflecting cavity. This is less effective than the elliptical geometry shown above but is still used since the Nd:YAG doesn’t require a very large amount of incident light (although it does need light whose wavelengths coincide with that of the absorption bands of the Nd:YAG) to cause a population inversion between the two lasing levels in the Nd:YAG (as explained earlier).

Fig

7. Cylindrical Reflecting Geometry

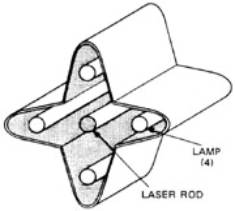

Other variations on the geometries used include those of the four lobe elliptical reflector and the spherical reflector as shown below.

Fig 8. Four lobe elliptical Reflecting Geometry

This geometry is good for lasing rods that require quite a lot of illumination to retain the needed population in Continuous Wave mode.

Fig

9. Spherical Reflecting Geometry